FSPP – Flame Spray Polypropylene

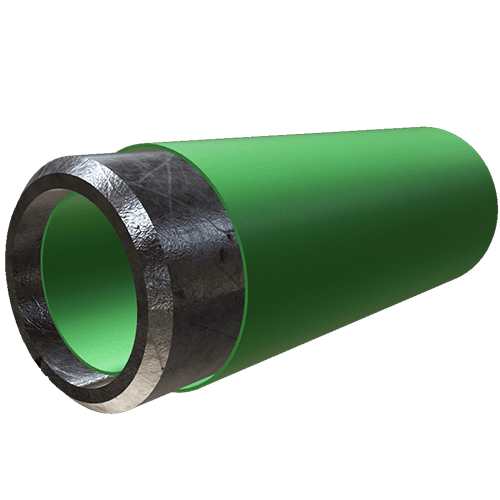

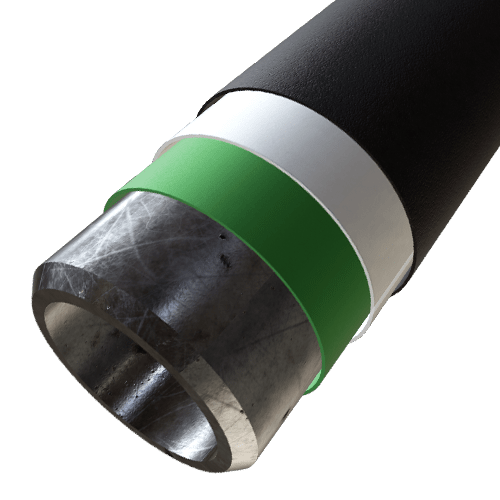

EXTERNAL COATING

V.I.P. Verniciatura Industriale Pesarese Srl is offering FSPP Flame Spray Polypropylene coating for pipelines.

Flame Spray Polypropylene (FSPP) technologies are particularly useful with custom pieces, bends, buckle arrestors etc., items whose shapes are difficult to coat. Powder is carried in a stream of air and is fed into the center of an annular combustion flame where it is heated.

A second outer annular nozzle feeds a stream of air, around the powder stream, which accelerates the spray particles toward the substrate and prevents burning of the powder.

Long-term anticorrosive protection

The FBE primer offers an excellent adhesion to the substrate and provides a long-term corrosion protection for pipelines operating at moderate temperatures. It also ensures resistance to cathodic disbondment so the total cost of cathodic protection of the pipeline decreases.

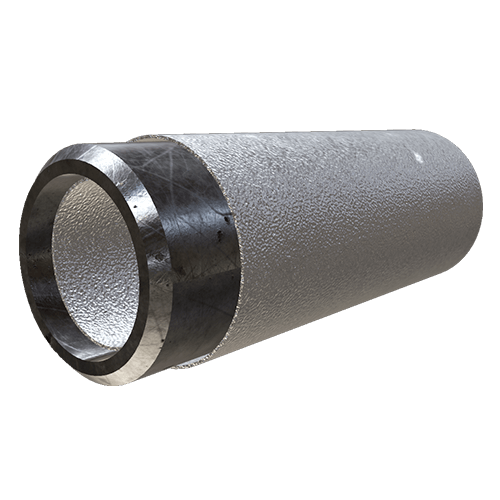

Very good mechanical protection

The layer of applied polypropylene protects the pipeline during transport and installation, thus reducing repair costs and guarantees underground protection against mechanical, chemical and abrasive. The thicker the applied polypropylene the higher the obtained mechanical protection.

Other advantages of the sintered system

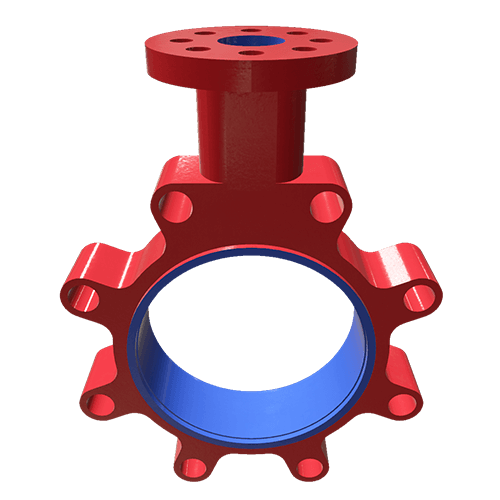

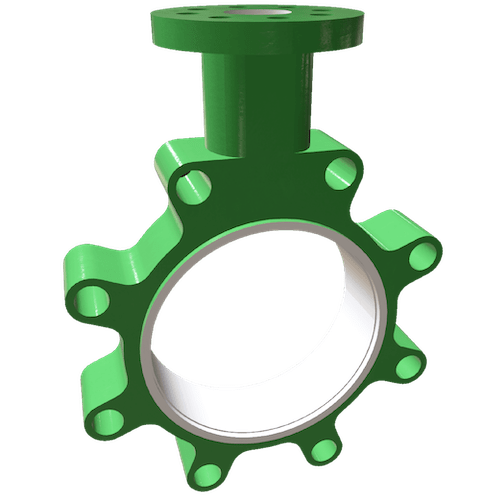

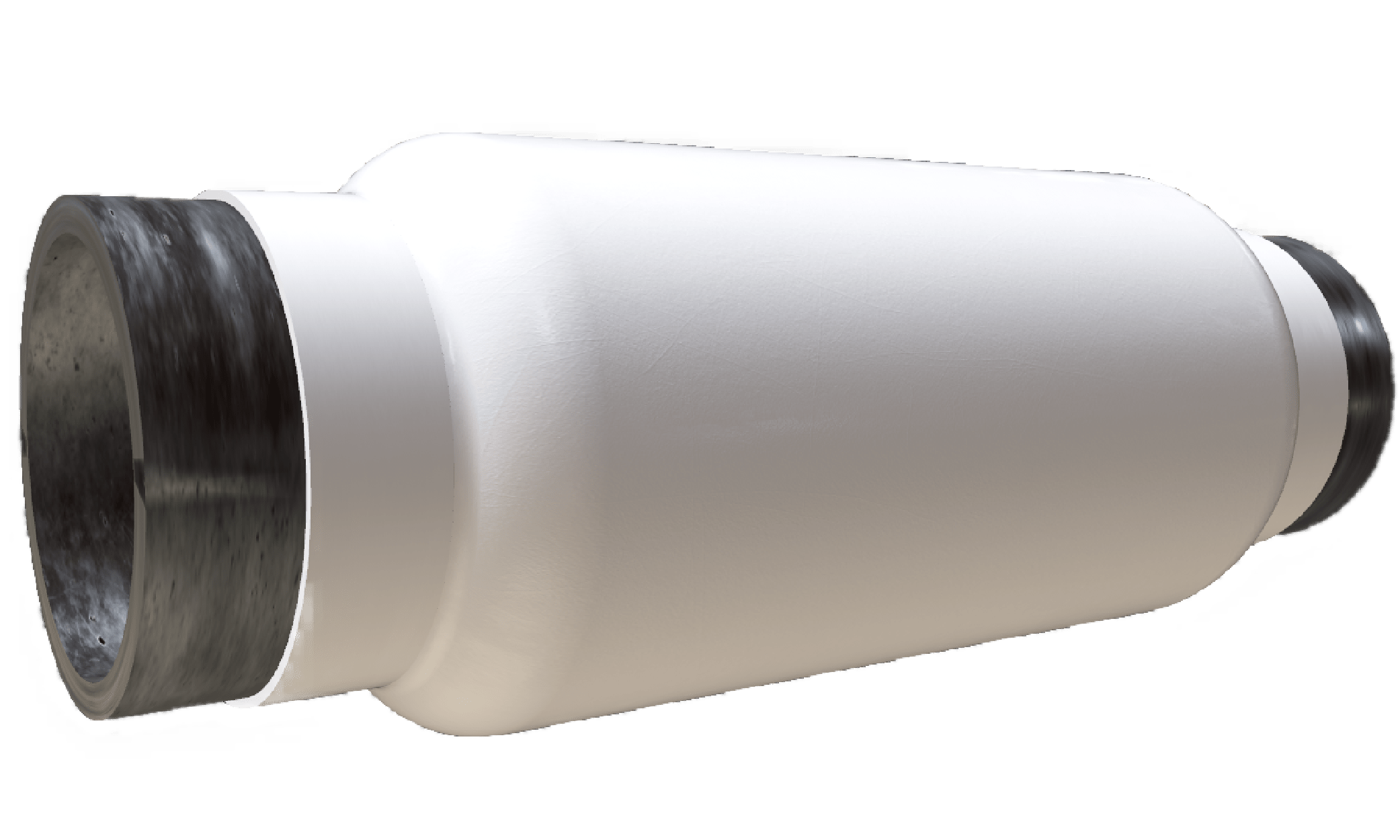

V.I.P. using this special application technique is able to coat also specific pieces with special shapes (bends, tees, reducers, joints, etc.).

There aren’t any limitations about the amount of pieces to coat, even the single piece can be treated. 3LPP can be applied in different thicknesses to meet the requirements of the project specifications.

- Buckle arrestors

- Small and large pipes

- Standard and special fittings

- Wide radius bends

- Flanges

- Field joint

- Custom pieces

- Elongation at Break : > 600%

- Hardness: Shore D 63

- Minimum recommended temperature : – 20°C

- Maximum recommended temperature : + 110°C

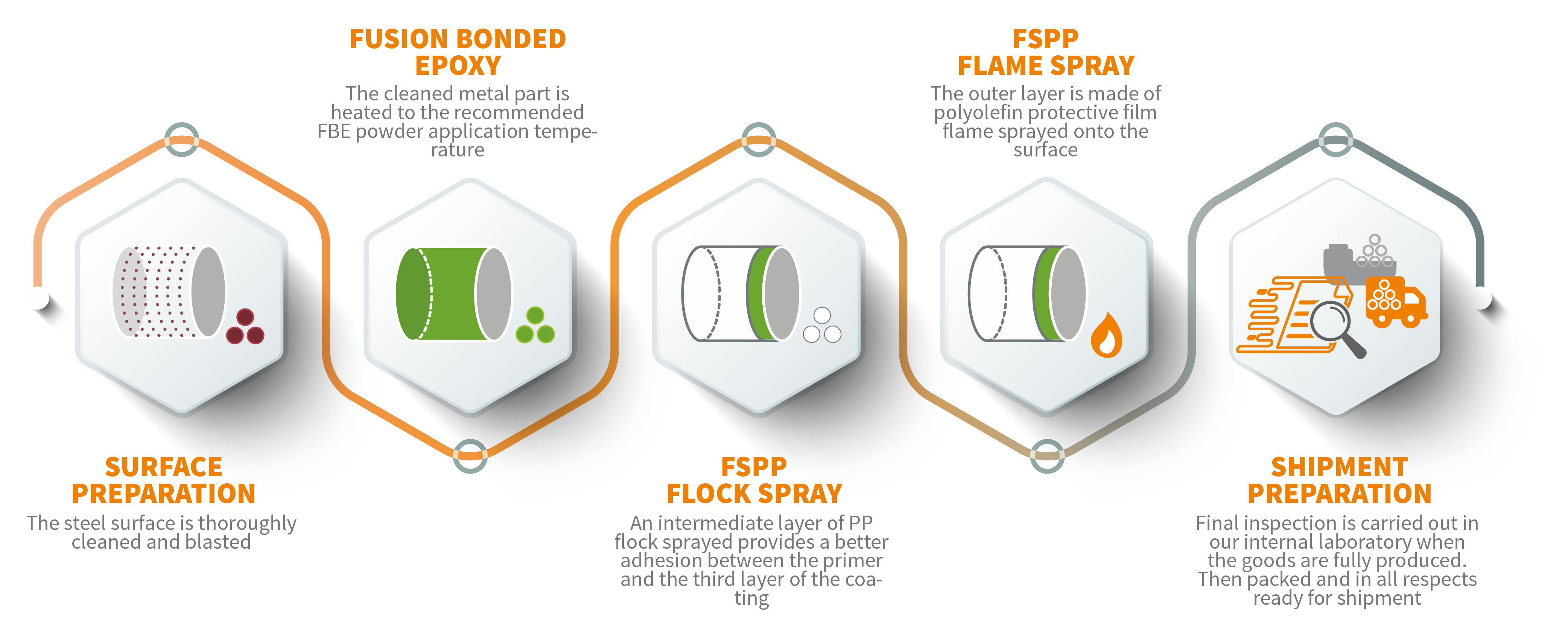

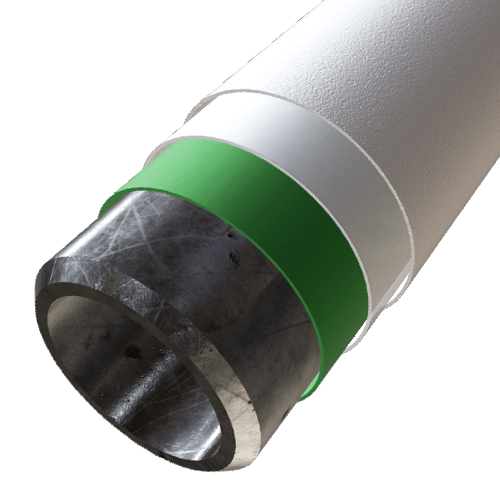

- SURFACE PREPARATION : The steel surface is thoroughly cleaned and blasted.

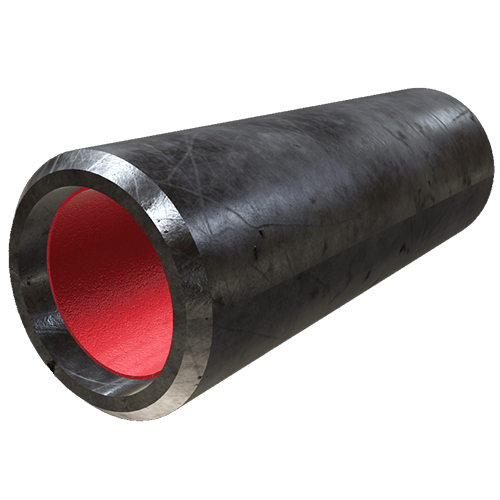

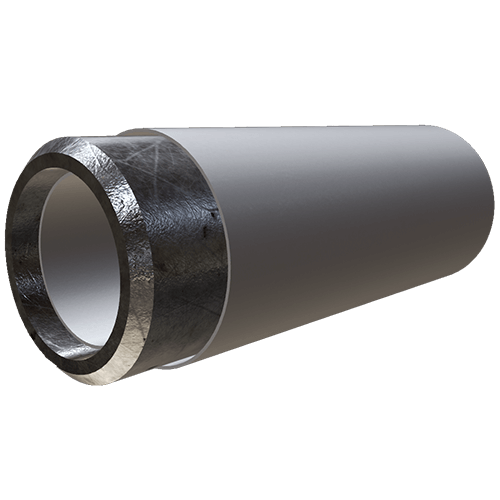

- FUSION BONDED EPOXY – Anticorrosive coating* : The cleaned metal part is heated to the recommended FBE powder application temperature.

- FSPE FLOCK SPRAY : An intermediate layer of PP flock sprayed provides a better adhesion between the primer and the third layer of the coating.

- FSPE FLAME SPRAY – Top coat : The outer layer is made of polyolefin protective film flame sprayed onto the surface.

- SHIPMENT PREPARATION : Final inspection is carried out in our internal laboratory when the goods are fully produced. Then packed and in all respects ready for shipment.

*Sintering is the coating process where a coating powder is sprayed on a preheated piece. Thanks to the heat emitted from the surface the powder fuses creating an homogeneous and continuous layer.

FBE (Fusion Bonded Epoxy) is the best epoxy resin powder applied on pre‐heated surfaces. Thermosetting coating designed for the anticorrosive protection of articles destined to immersion or buried services in oil and gas sector and in the protection of the water pipeline.

FSPP PROCESS

EXTERNAL COATING

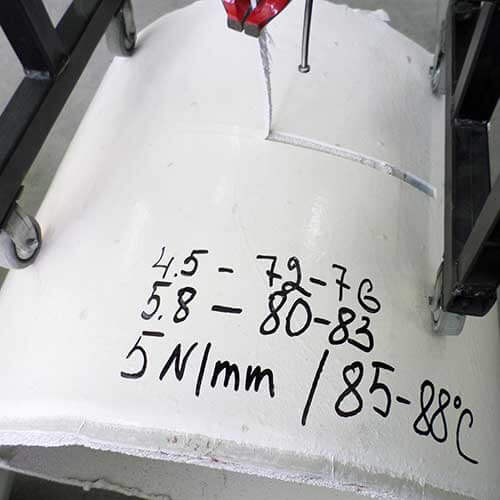

GENERAL TESTING

These are merely approximate values adjustable according to clients’ requirements.

| Property | Test Description | Typical Values |

|---|---|---|

| Degree of cure of epoxy resin | ISO 21809/1 | ∆Tg according to the manufacturer specifications |

| Impact | ISO 21809/1 | > 10 J/mm |

| Cathodic Disbondment | ISO 21809/1 | 23°C/ 28 days or 60°C/ 2 days max 7 mm |

| Peel Strenght | ISO 21809/1 | ≥ 25 N/cm at 23°C; ≥ 4 N/cm at 90°C |

| Continuity (holiday detection) | ISO 21809/1 | 10 kV/mm; max 25kV |

COATING CAPACITY

Pipes:

Diameter from 1/2” to 120”

Maximum unit length 13.5 meters

Maximum unit weight 15,000 kg.

Joints and/or custom pieces: (bends, tees, reducers, flanges, etc.)

Maximum size 3.0 x 3.0 x 13.5 meters

Maximum unit weight 15,000 kg

Maximum thickness of the coating 3,5 mm