Bus Bars – Coated with Resicoat® EL3

Eco-Friendly Power Distribution for a Greener Future

Sustainable Energy

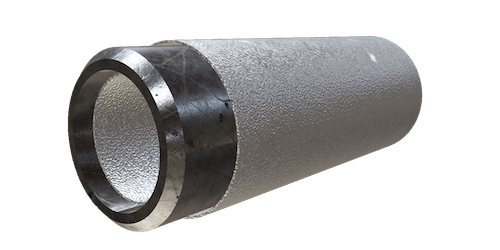

As the global demand for sustainable energy solutions grows, so does the need for reliable, efficient, and long-lasting electrical components. One of the key elements in modern electrical systems is the bus bar — a conductive metal strip used to distribute power within switchgear, distribution boards, and a wide variety of electrical devices.

At V.I.P. Verniciatura Industriale Pesarese Srl, we specialize in industrial coating solutions and offer advanced protection for bus bars using Resicoat® EL3, an epoxy powder coating applied by fluidized bed immersion. This method ensures top-tier electrical insulation, environmental protection, and mechanical durability.

What about the coating

Resicoat® EL3 is a high-performance epoxy coating system developed by AkzoNobel. It is specifically designed to provide electrical insulation and corrosion protection for copper or aluminum bus bars and conductive parts used in medium- and low-voltage applications.

The fluidized bed coating process involves heating the metal part and immersing it in a tank of suspended epoxy powder. The powder melts on contact, creating a seamless, uniform, and highly adhesive coating — ideal for complex geometries and high-performance requirements.

Coating System for Bus Bars

01. Key Benefits of Resicoat® EL3 Coatings

-

Superior electrical insulation

Prevents electrical arcing, short circuits, and dielectric breakdown. -

High corrosion and chemical resistance

Ensures long-term durability in humid, salty, or chemically aggressive environments. -

Uniform thickness and coverage

Guarantees consistent performance across all coated surfaces. -

Strong mechanical protection

Reduces the risk of damage from vibration, impact, and wear. -

Eco-friendly process

The coating is applied without solvents or VOC emissions, making it a sustainable choice for modern industries. -

Thermal stability

Performs reliably in both high and low temperature conditions.

02. Green Applications of Coated Bus Bars

Bus bars coated with Resicoat® EL3 are increasingly used in clean energy and low-carbon technologies. Their excellent insulating and protective properties make them ideal for:

Renewable Energy Systems

- Solar power plants (PV systems) – internal connections in inverters and DC/AC distribution panels

- Wind turbines – power conversion units and control cabinets exposed to moisture and salt air

- Hydroelectric power stations – corrosion-resistant electrical infrastructure

Electric Mobility and Transport

- EV fast charging stations – high-voltage electrical insulation in compact assemblies

- Electric buses and rail – distribution panels and traction systems for public transport

- E-bike and e-scooter charging hubs

Energy Storage & Smart Grids

- Battery Energy Storage Systems (BESS) – safe and compact power bus bars

- Microgrids and smart distribution units – modular and decentralized power systems

- Hydrogen and fuel cell plants – corrosion-resistant insulated components

Green Industrial and Infrastructure Projects

- Energy-efficient buildings – smart switchgear and busway systems

- Data centers – low-loss, thermally stable power distribution

- Sustainable manufacturing – electrical control units in clean production lines

Sustainable Surface Protection for Smart, Clean Energy Infrastructure

At VIP Verniciatura Industriale Pesarese, we offer advanced insulating and protective coatings for bus bars, designed to meet the demanding requirements of modern electrical systems in renewable energy, e-mobility, industrial automation, and power distribution infrastructure.

We handle both single components and high-volume production, ensuring flexibility for custom engineering projects as well as large-scale installations.