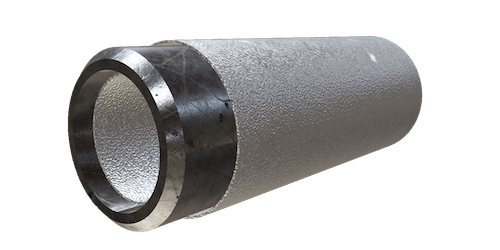

Bends Coating – Tailor-Made Solutions for Critical Pipeline Components.

High-performance coatings for bends from ½” up to 120”, single or large batch production

Technical Capabilities

- Diameter range: from ½” to 120”

(DN15 to DN3000) - Maximum unit length: 13.5 meters

- Maximum unit weight: 15,000 kg

Thanks to dedicated facilities and specialized handling equipment, we are able to coat large-diameter bends and complex geometries with the same precision and quality guaranteed for smaller fittings.

Applications

- Oil & gas pipelines (onshore and offshore)

- Water transportation

- Petrochemical plants

- Heavy industry piping systems

Shipping

- Custom packing (crates, settles, pallets)

- Container stuffing

- Heavy/bulky goods loading

Coating Systems for Bends

01. Sintered 3LPE / 3LPP

- High-performance anticorrosive system widely used in oil & gas pipelines

- Excellent mechanical resistance against impact and abrasion

- Perfect adhesion thanks to sintering process

- Compliant with international standards

02. FSPE / FSPP

- Polyethylene (PE) or Polypropylene (PP) applied by flame spray technique

- Guarantees high adhesion and mechanical strength

- Ideal for complex shapes, bends, and field joints

- Suitable for high-temperature and buried pipeline applications

- Excellent corrosion protection, combined with abrasion resistance

03. Tape Coating Systems

- Certified solutions for field joint coating and rehabilitation works

- Available with polyethylene or polypropylene backing

- High flexibility for bends with complex geometries

04. PUF

- Polyurethane Foam Insulation

- Thermal insulation for district heating or industrial cooling networks

- Applied on bends and fittings for continuous thermal protection

05. Metallization

- the only one in Italy QP6 Certified

- Zinc or aluminum metallization for cathodic protection

- Approved QP6 process for anticorrosive applications in demanding environments

06. Other coating systems available:

- Epoxy-based coatings (single or multilayer)

- Zinc-rich primers

- Polyurethane topcoats (UV-resistant)

- Discover all available solutions for bends

High-performance coatings for bends up to 120”, single or large batch production

At VIP Verniciatura Industriale Pesarese, we offer advanced anticorrosive coatings for pipe bends and fittings, specifically designed for critical pipeline infrastructures in oil & gas, water transport, petrochemical, and industrial plants.

We handle single pieces as well as large-scale batches, providing flexibility for small custom projects or major pipeline developments.