POLYOLEFIN COATINGS

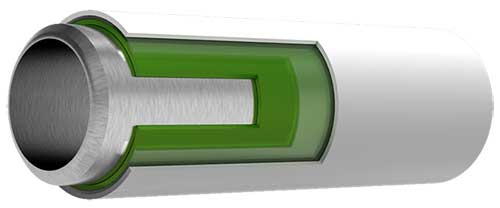

Polyolefin coating systems combine the anti-corrosion properties of Fusion Bonded Epoxy (FBE) with the mechanical protection of a Polyolefin (PP or PE). Between the first layer of FBE and the third layer consisted of a copolymer there is an adhesive layer. All together the three layers provide excellent protection against corrosion and a long lifespan of the pipeline.

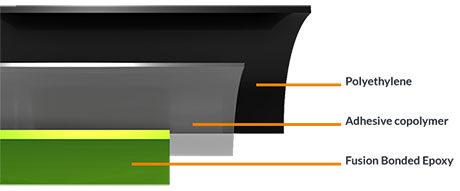

3LPE – Triple layer of polyethylene

EXTERNAL COATING

INTERNAL LINING

The coating is a multilayer composed of a primer fusion bonded epoxy (FBE) followed by an adhesive copolymer and another layer of polyethylene which provides resistance and long-lasting protection.

The system ensures the applicability of the sintered coating also on pieces with special shapes.

3LPE can be applied in different thicknesses to meet the requirements of project specifications.

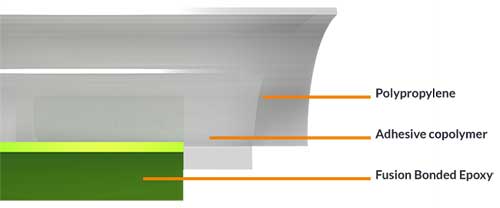

3LPP – Triple layer of polypropylene

EXTERNAL COATING

INTERNAL LINING

The coating is a multilayer composed of a primer fusion bonded epoxy (FBE) followed by an adhesive copolymer and another layer of polyethylene which provides resistance and long-lasting protection.

The system ensures the applicability of the sintered coating also on pieces with special shapes.

3LPE can be applied in different thicknesses to meet the requirements of project specifications.

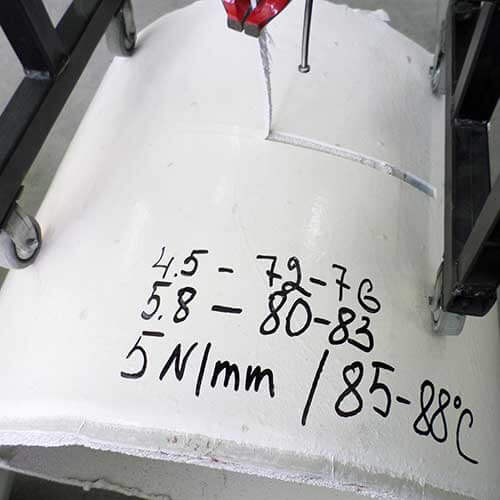

FSPP – Flame Spray Polypropylene

EXTERNAL COATING

V.I.P. Verniciatura Industriale Pesarese Srl is offering FSPP Flame Spray Polypropylene coating for pipelines.

Flame Spray Polypropylene (FSPP) technologies are particularly useful with custom pieces, bends, buckle arrestors etc., items whose shapes are difficult to coat.