FUSION BONDED EPOXY LINING

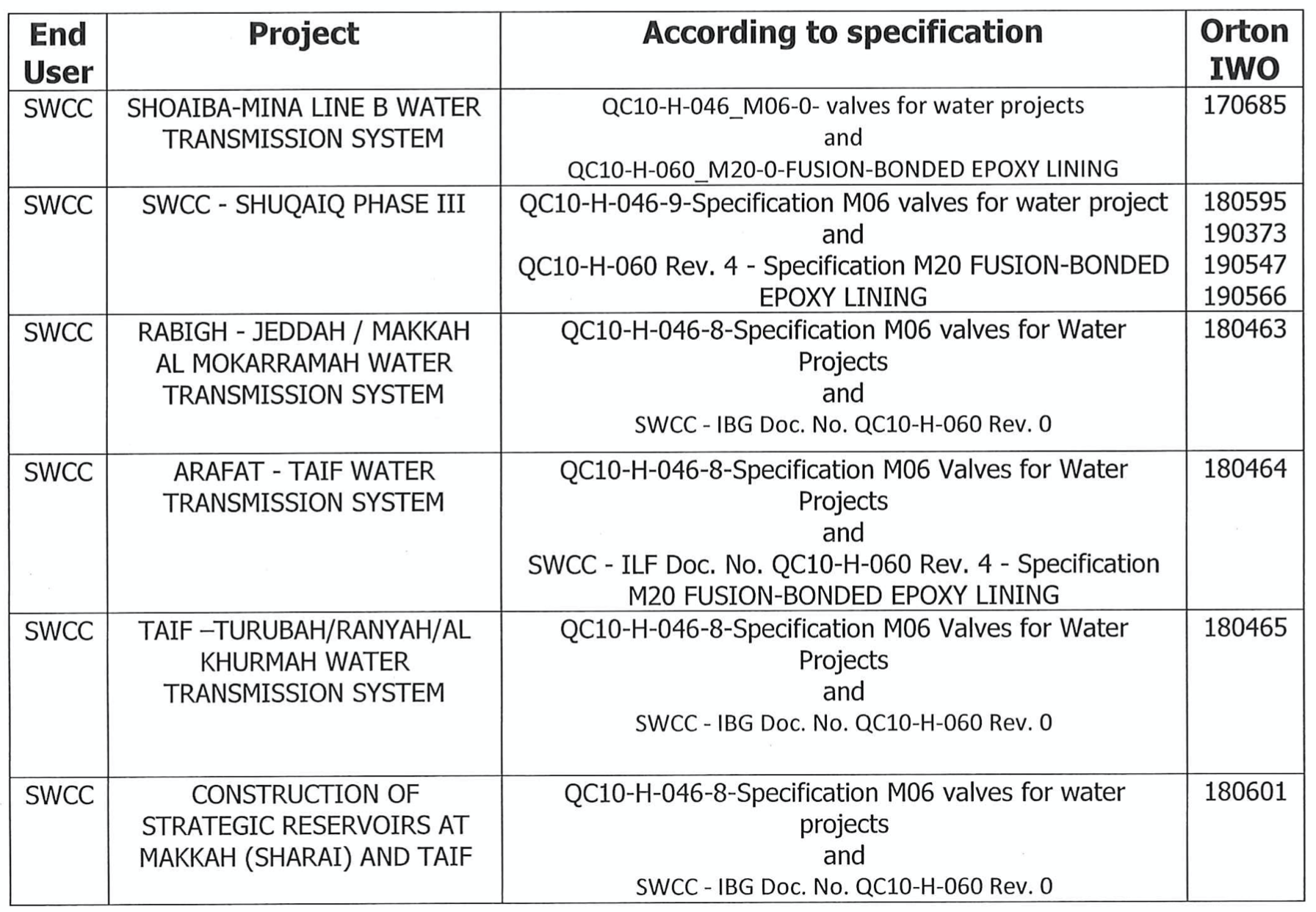

Saline Water Conversion Corporation (SWCC)

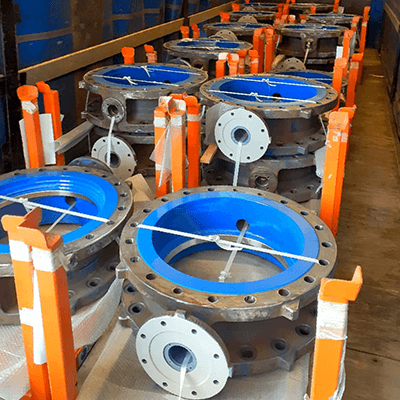

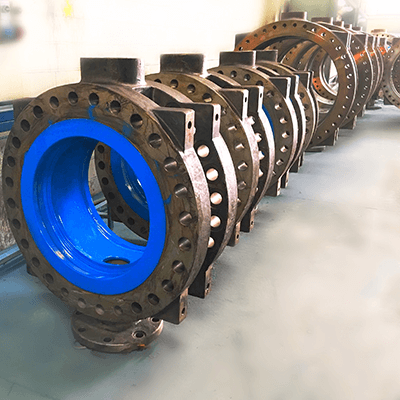

F.B.E. Lining on IMI ORTON’s valves for Saline Water Conversion Corporation (SWCC)

V.I.P. Pesaro is one of the few companies able to offer the best quality on pipes as well as on custom pieces.

Thanks to almost thirty-years experience we constantly develop new products introducing new technologies to obtain impeccable results.

The Saline Water Conversion Corporation (SWCC) is a Saudi Government Corporation responsible for the desalination of seawater producing electric power and supplying various regions in the Kingdom with desalinated water.

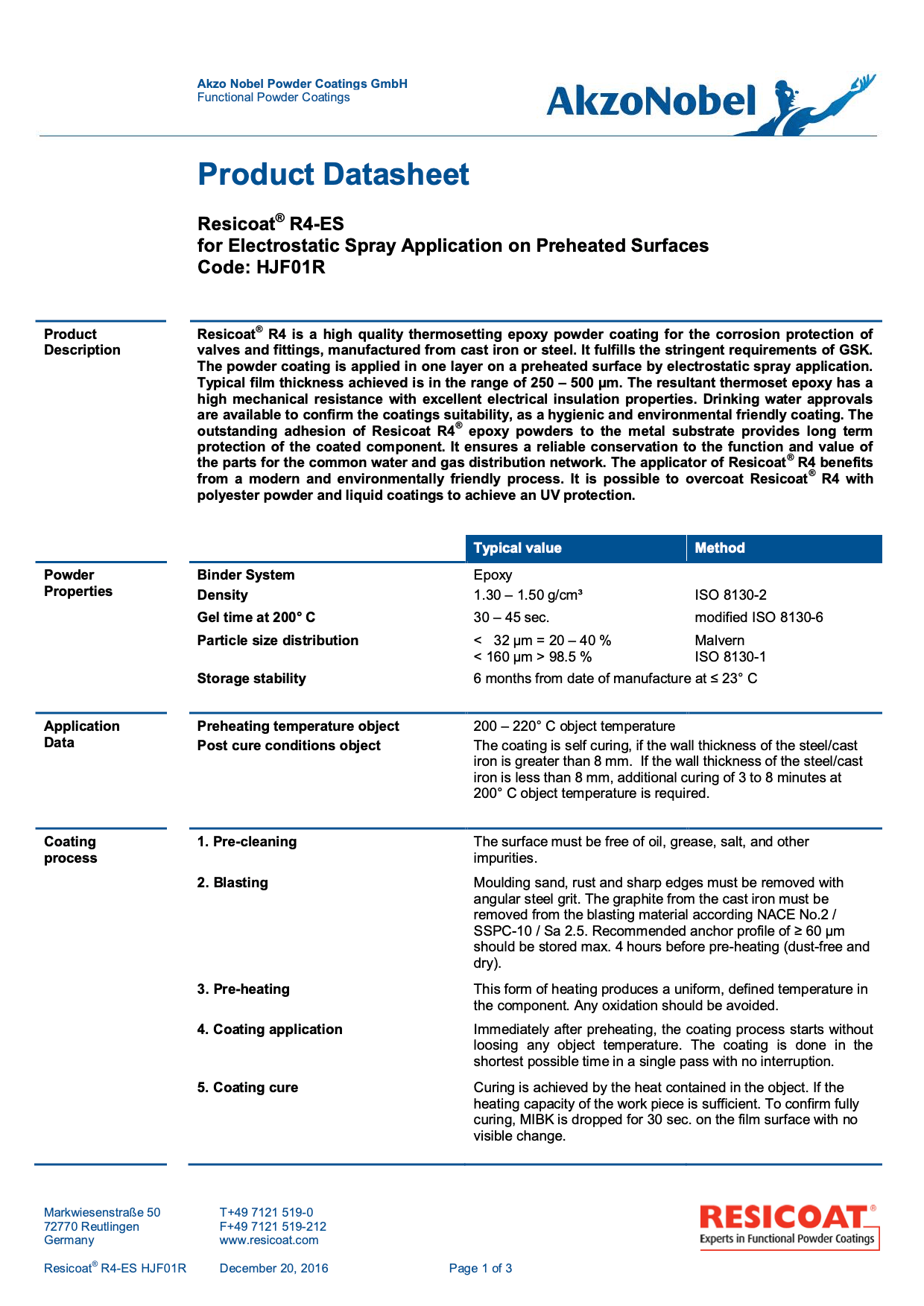

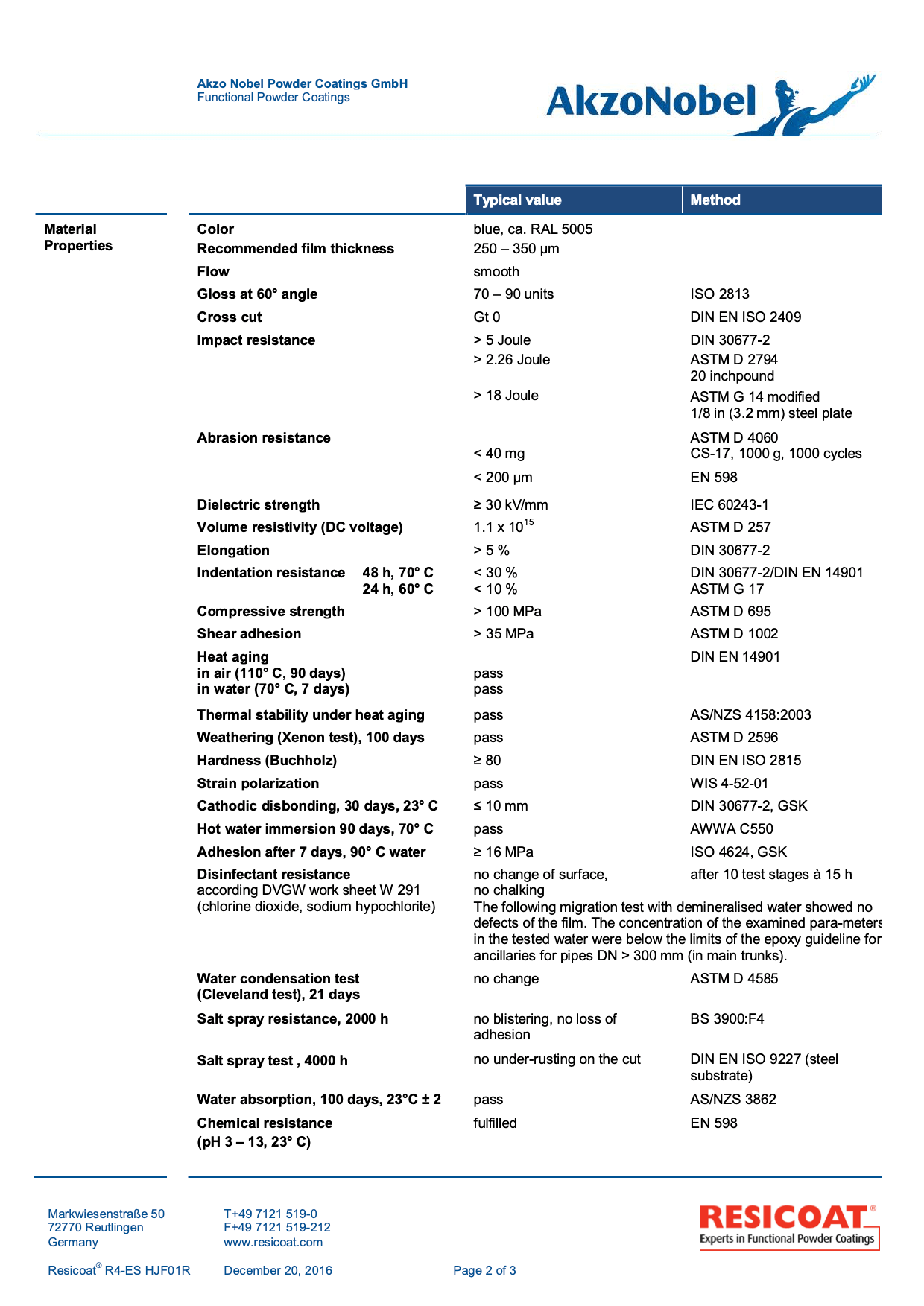

Product Datasheet

Resicoat® R4-ES for Electrostatic Spray Application on Preheated Surfaces

OUR SATISFIED CLIENTS

VIP Verniciatura Industriale Pesarese has applied FBE lining on Orton Valves.

Currently not all valves are in operation, but as of today we not have encountered any technical problems on FBE lining on testing activities at Orton’s plant.