Polyurethane foam

PU foam

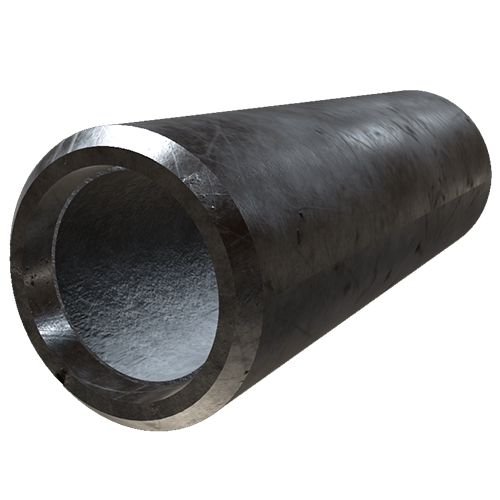

EXTERNAL COATING

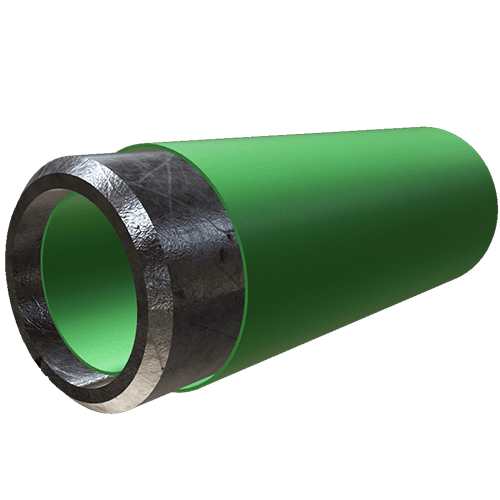

PU foam pipes and/or bends coating is added on the external surface of pipelines when thermal insulation is required. The fluid flowing inside the line maintains its viscosity thanks to superior insulation properties and low thermal conductivity.

The coating reduce heat loss and prevent hydrate formation in subsea gas pipelines. The foam is injected between the pipe and an HDPE (high density Polyethylene) jacket, according to EN 12 201, the jacket is custom cut in case of bends.

V.I.P. Pesaro is one of the few companies able to offer the PU foam coating on pipes as well as on custom pieces.

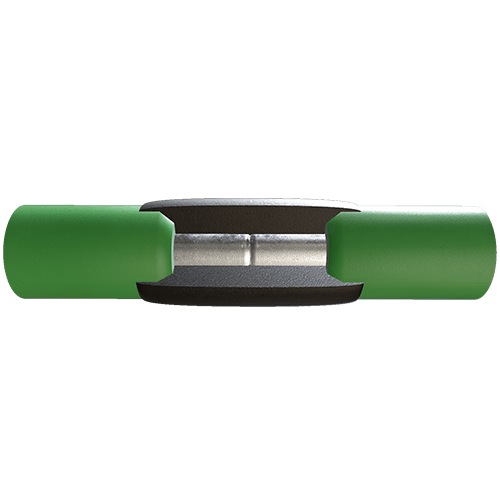

The coating is a multilayer composed of a primer fusion bonded epoxy (FBE) followed by a layer of polyurethane foam and an outer casing of polyethylene which provides resistance to high temperatures, thermal insulation and long-lasting protection. Especially recommended for district heating pipes, this pre-insulated bonded pipe system for directly buried hot water networks is designed for a constant flow of hot water at 120/140°C of temperature.

District heating pipes

Pre-insulated bonded pipe systems for directly buried hot water networks. It is a three layers pipe assembly of steel service pipe, polyurethane thermal insulation and outer casing of polyethylene. The polyurethane foam has a very low thermal conductivity, which is due to the porous structure and the low conducting gases trapped in the cells of the foam.

Thermal insulation

Thanks to the level of thermal conductivity and its rate of degradation can be interpreted as an economically and environmentally cost or gain. This coating is mainly used for hot fluid transportation from thermal power stations to factories as well as residential units, o!en are widely used for the transport of oil and chemicals and for district heating and cooling systems.

About the foam layer:

. Foam density: 80Kg/m^3 ASTM D1622

. Foam initial thermal conductivity at 23°C: 24 mW/mK UNI7891

. Foam compression resistance: 300KPa UNI6350

- Small and large pipes

- Standard and special fittings

- Wide radius bends

- Flanges

- Valves

- Tanks

- Buckle arrestors

- Waterworks components

- Field joints

- Custom pieces

Trasversal resistivity (23°C): >10^17 Ωcm according to DIN 53482

- SURFACE PREPARATION : The steel surface is thoroughly cleaned and blasted.

- FUSION BONDED EPOXY : The cleaned metal part is heated to the recommended FBE powder application temperature.

- JACKETING : PE jacket preparation. In case of bends the jacket is cut to be folded around and perfectly fit the shape.

- PU FOAM INJECTION : Polyurethane foam is injected at the right density to fill the gap between the pipe and the polyolefin jacket.

- SHIPMENT PREPARATION : Final inspection is carried out in our internal laboratory when the goods are fully produced, packed and in all respects ready for shipment.

PU FOAM PROCESS

EXTERNAL COATING

INSPECTION AND TESTING

These are merely approximate values adjustable according to clients’ requirements.

| Property | Test Description | Typical Values |

|---|---|---|

| Thermal conductivity (23°C) | DIN 52612 | 0,38 W/m°C |

| Elongation at break | EN ISO 6259 | >350% |

| Oxydation induction time | EN 728 | >20min at 200°C |

| Hydrostatic strength | UNI EN 921 | >170h at 80°C – 3.0MPa |

| Final density | ISO 1183 | >950 Kg/m^3 |

COATING CAPACITY

Pipes:

Diameter from 1/2” to 120”

Maximum unit length 13.5 meters

Maximum unit weight 15,000 kg.

Joints and/or custom pieces: (bends, tees, reducers, flanges, etc.)

Maximum size 3.0 x 3.0 x 13.5 meters

Maximum unit weight 15,000 kg

Maximum thickness of the coating 3,5 mm